Leading Concrete Floor Coatings Perth

Servicing all of Perth, Hawk CFC has over 10 years of experience providing premium durable coating solutions

Request a Free Consultation

Our Trusted Clients

High-Quality Concrete Floor Coatings

Hawk CFC has been in operation for over a decade and specialises in the specification and installation of concrete floor coatings for residential, commercial, industrial, and mining applications.

The surface you walk on happens to be vitally important to the running of any workplace, and the last thing you need is a poor-performing or unfit finish. Still, there’s a surprising amount to consider when it comes to selecting the right floor coating.

At Hawk CFC, we’ve been supporting our Perth clients for almost a decade with a range of leading products and custom resins. Some of the most popular concrete floor coatings in Perth include:

- Epoxy options

- Polyurethane options

- Polyaspartic options

- Methyl Methacrylate (MMA) options

However, we understand that the right solution for you will be bespoke, and one size does not fit all. So reach out and speak to a member of the Hawk CFC team today on 0490 777 761 or request a 100% obligation-free quote online today.

How do I know if concrete floor coatings are right for me?

The range of options available is designed to protect your underlying floors from wear and tear. But, with numerous options available, it’s one thing to see the benefit of flooring protection – and another to know which option is right for you.

The typical application of a floor coating is protection, but this can be broken down to suit your needs. For example:

- Vehicle traffic

- Forklift traffic

- Foot traffic

- Decorative advantages

Your choice in the floor coatings should come down to the impact your surface is expected to take. For example, an epoxy with a higher shore hardness is suited for heavier vehicle traffic. However, it’s important not to compromise film thickness in the search for flexibility. Film thickness is important because it’s the “barrier” that protects your floor.

For more information, check out our premium resources:

- Best Concrete Finishes for Commercial Use

- What is Expoxy Resin (and why is it so popular?)

- How Does Heavy Traffic Affect a Resin Floor?

Leading performance conditions to take into account

Your choice of flooring will be dictated by four primary performance conditions. These include:

Chemical Exposure

Splashes and spills may be common in your industrial setting or work site, but it’s constant immersion that will dictate more robust floor coatings.

Impact Damage

Vehicles and heavy load impact can weaken or damage the surfaces, requiring special treatment for long-term impact.

Abrasion

What type of traffic will you be dealing with? The difference between steel-wheeled traffic and rubber-wheeled traffic is significant when choosing the best option.

Thermal Shock

Temperature fluctuations will need to be addressed by your floor coating. Whether regular steam cleaning in a retail space or constant high temperatures, you’ll need to factor in the potential loss of bond via thermal expansion when making your choice.

How to choose the right floor coating

When choosing the best solution for your concrete surface, you’ll need to factor in a range of variables, including:

- Top Coat Quality

- UV Stability

- Gloss Level

- Future Coat Application (e.g. line marking)

Polyurethane is a great choice for a topcoat when a higher level of scratch resistance is required, or when self-levelling/self-smoothing epoxies have been used. Polyurea and Polyaspartic are also good options as a topcoat. Non-slip granules can be added in to provide a slip rating, so speak to a Hawk CFC expert for help choosing the right option for you.

What level of floor preparation is required?

Concrete floor coatings require a solid surface to bond to. If there are doubts about the integrity of the surface (for example, oil contamination, soft concrete surface, previous coatings or hardeners, surface preparation limitations, high moisture areas) then the right primer is essential.

Moisture Tolerant primers, oil-resistant primers, and consolidating primers are available. A primer will need to be selected that is compatible with subsequent coats. Your choice of concrete floor coating may also require concrete grinding as part of the surface preparation.

Learn more about concrete grinding here.

Can I use any type of concrete floor coatings to get the job done?

No.

It’s tempting to opt for the most economical choice, but any supplier or installer who claims ALL floors can be completed with the same basic miracle resin is selling you a lie.

For example, epoxy is a great product to use in many applications, but not all. Polyurea and Polyaspartic systems are often touted as the “complete product,” yet fall short in many scenarios. A balanced and experienced view is required when making product selections.

How much do concrete floor coatings cost?

The short answer is “it depends”.

With numerous options available, the price you pay will come down to your choice of coating, the level of preparation required, the size of your concrete surface, and the complexity of the job.

Generally speaking, a polyurethane system will cost more than epoxy but can be more cost-effective in the long run. With a lifespan double that of epoxy in heavy-duty or commercial areas (10 years vs. 5 years), it’s important you take all pricing factors into account, not just the initial labour and installation.

Looking for more pricing information? Find out how much epoxy resin costs here [2022 Guide]

Quick Recap: Your concrete flooring system options

It’s easy to feel overwhelmed by the amount of choice on offer when it comes to your concrete floors. Whether you’re running a business or managing a worksite, it’s important you’re equipped with all necessary information.

Here’s a quick recap of your concrete flooring options:

| Thickness | Polymer Type | Appearance | Finish |

|---|---|---|---|

|

Thin (1 – 10 mils) High Build (10 – 30 mils) Slurries (40 – 125 mils) Toppings & Overlays (125 mils – ½ inch) |

Epoxy Polyurethane Polyester Methacrylic |

Functional

Decorative Transparent Coloured |

Smooth

Textures Matte High-Gloss High-Shine |

What warranties do you offer?

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical, and equipment workshops – so we know the surface under your feet (or the feet of clients, customers, and team members), needs to be robust and reliable.

As the only West Australian installation company with its own local manufacturing plant, we can handle the entire process from production to installation to save you money. And to provide leading peace of mind, we offer a Delamination Warranty that covers both materials and workmanship.

Hawk CFC has developed a reputation for specifying the right coatings for the right applications and following through with correct surface preparation and application.

For further information and pricing about concrete floor coatings feel free to get in touch via phone (0490 777 761) or contact us online.

Truck Shed

Retail Supermarket

Commercial Floor

Retail Store

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

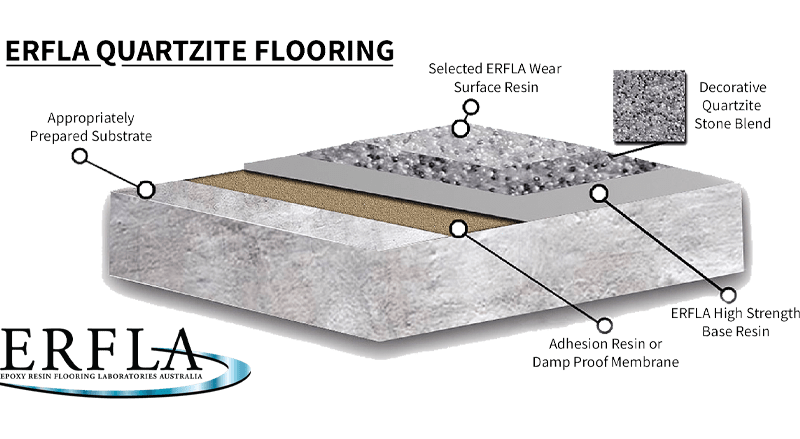

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.