High Quality Epoxy Flake Perth

Contact us today to find out more about our options.

Request a Free Consultation

Our Trusted Clients

Specialists in Epoxy Flake

Epoxy flooring is among the most durable and utilitarian options available for homes and businesses – but that doesn’t mean it has to lack character or design. With just a bit of epoxy flake, you can add a one-of-a-kind style that matches your aesthetic or brand.

In the quest for long-lasting, eco-friendly, and low-maintenance floor, this material rises to the top of almost any search. Applied in multiple coats to an existing concrete slab, this type adds protection from pretty much anything life, or your family and customers, throws at it. However, many are turned off by the idea of adding a clear coat to gray concrete

This is not what the floor is limited to. In fact, it is one of the most easily customisable at a fraction of the cost of floors like tile or wood. Just a sprinkle of this material can create instant visual interest. And it comes in a variety of colours, sizes, and textures that can combine with pigments and coatings to create depth, design, and even distract from occasional dirt.

This type of floor takes a practiced hand to install properly. That’s why homes and businesses in Perth and WA turn to Hawk CFC. We’ve served the area since 2014 with manufactured products and services that we stand by. We’ll be happy to walk you through the options that meet your project needs and budget. Call us on 0490 777 761 to learn more!

What exactly is epoxy flake and what makes it special?

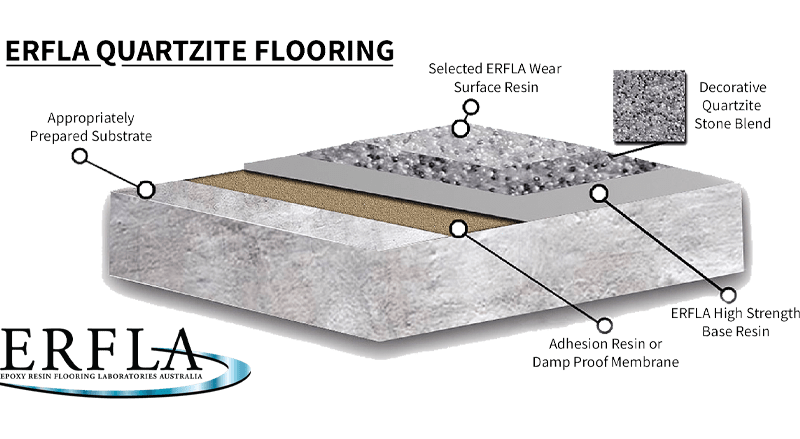

Let’s start by making sure we’re clear (pun intended) on what this type of floor is. Simply put, this flooring is made up of resin and hardener applied in coatings to an existing floor, usually concrete, as a clear liquid and that dries to create a hard coating. Adding extra coatings can add to the floor’s durability as well as the overall look. Each layer takes some time to cure in between applications to ensure a proper bond.

Flake, also known as broadcast, is a substance that is added in between layers of resin to create a speckled or confetti effect. The term broadcast comes from an application method where this material is scattered and allowed to fall naturally, creating a unique pattern. The amount used depends on how much colour and visual interest you want in your floor.

It itself is usually made of vinyl or acrylic pieces that come in a variety of sizes and colours. From larger chips to smaller flecks, there are hundreds of different shades and blends available. You can even create your own blend by choosing several colours and mixing them together before application. The floor is finalised with a top coat to seal in all of the layers and create a safe, effective surface to walk, drive, or work on.

The result is a custom floor that is truly one of a kind. Businesses can choose any combination of the layers for their floors to add design interest, match branding colours, or hide any small scratches or signs of foot traffic over time. They can also be added in multiple layers to add depth to the design.

When is this resin a good option to add to the floor in Perth?

What to spice up your space?

Epoxy flake is an easy, affordable way to jazz up your floor. Adding acrylic or vinyl chips to the mix can make a great floor and amazing one with a design that can outshine even granite or quartz at a fraction of the cost.

Specifically, this material is excellent in high traffic areas where you might want to distract from dirt or scuffs in between cleanings. This is common in commercial spaces like garages, office buildings, or retail stores. But homeowners are increasingly choosing this option for their mudrooms, common living spaces, bathrooms, and even outdoor entertaining areas.

The best part is that the flake has all of the perks of a regular flooring and can be used in any number of spaces.

Does this type of floor require special care?

This is another great perk when it comes to this type of flooring. Little to no maintenance is required beyond regular cleaning. And even cleaning is straightforward. No harsh chemicals are needed (in fact, they can degrade the lamination over time if used). Simple sweep up or use a damp mop – soap and water will do – to wipe away any dust, debris, or spills on your floor. The floor itself will protect against the rest.

Of course, if you are installing your floor in a high-traffic area, time will take its toll. However, you can expect your floors to last for 10-20 years depending on just how hard you are on them. For homes and commercial spaces, 20 years is a fair estimate. In more industrial applications, 10 years could be the limit.

However, once this floor is past its prime, you don’t have to completely replace the floor itself. A professional service can come in and reapply the coatings over the existing concrete substrate if you prefer. And with regular cleaning and an occasional top coat, you can prolong the life of the floor.

How wide of a variety is there?

Your imagination – and budget – are the limit here.

This material come in hundreds of colors and packaged mixes to suit any business design needs. It comes in solids as well as glitter and metallics (and even glow-in-the-dark varieties!), so you go as subtle or as stand out as you want. You can also have blends specially prepared to create a custom color combo that’s unique and eye-catching.

While every flake will be a bit different, they generally come in sizes including 1mm (fine), 2mm (micro), 4mm (small), and 6mm (large). You can even mix the sizes up along with the colours for a textured look that is special to your flooring.

Why your professional installer really matters

This material is an artform that requires creativity and precision. Broadcasting the flakes is just one component of the installation. Leave this to anyone other than an experienced expert, and you might end up with a floor that’s more unique than you bargained for. And what’s more, the integrity of the flooring itself can be compromised by improper installation methods.

Look for a professional installer that has practical experience designing the blends that meet specific client aesthetic needs. Ask to see samples and a portfolio, or – better yet – ask to speak with a few customer references about their experience.

Some installers will create a sample for you to show you what your specific blend could look like to make sure you are on the same page before you do an entire floor in that design. Others can recommend an approach based on your existing branding or the intended use of the floor itself to ensure the right number of coatings and proper protection.

An incorrectly installed floor can crack, peel, discolour, and degrade over time, leaving you with a mess and a floor that begs to be redone. As you explore professional installers, look for those who:

- Are licensed and insured to do the specific work you need

- Have direct experience working with this material

- Are local and available on the timeline you need

- Employ their own staff instead of relying on subcontractors

- Can make best practice recommendations for your needs

- Back all of their work and materials with a warranty you can rely on

Call on Hawk CFC for your project

Not only do we stand by our installation, but we also manufacture the materials we use in every customer application. We’re experienced in commercial and residential applications and love to collaborate with clients on the best blends and color palette for their spaces.

Choosing a new floor should be a creative and straightforward experience when you use the right contractor. Hawk CFC ensures this for every customer with hands-on service dedicated to sticking to timelines and budgets. We look forward to helping you design a floor for your unique space. Just call us on 0490 777 761 to learn more about our process.

Frequently Asked Questions About Perth Epoxy Flake Flooring

What are the most common spaces where this type of flooring is used in Perth?

This is such a diverse product that it can be used nearly anywhere you want to install it. These tend to be very popular in garages and commercial spaces like hotel or office lobbies where there is high traffic and a constant influx of dirt. While you’ll want to keep up with the cleaning regardless to extend the life of your floor, the patterning in a the design can hide the appearance of anything tracked in during sweeps.

How many layers do I need?

This is variable depending on the design you want and the budget you are working with. The floor will have a base coat without any flake in it to provide a good foundation for the decorative elements. Then you can include colour flakes followed by a topcoat. But if you want more depth to the design, you can alternate layers for added thickness and visual interest. Double layering is a popular option and can last much longer than a single layer especially in high traffic spaces.

Does epoxy flake have to be a kaleidoscope of colour?

Not at all. While some projects make sense to pull in the rainbow, you can go with more neutral blends or stick with a single color pallet. You can also use flake in combination with pigmentation of the material itself to achieve a specific look. Using a finer texture with more neutral colours can still provide a designer look with depth and interest without looking out of place for your home or business.

Are there different kinds of broadcasts?

Absolutely! A full broadcast flake is one that is completely covered in many layers with little to no gaps in between. For these applications, an installer may need to use extra adhesive or thicker top coating to ensure a level and proper seal. At the other end of the spectrum, a light sprinkling will add a bit of visual interest while leaving the floor predominantly flake free. This is a great look when combining the flake with a pigmented coating. In between, you can find medium and heavy broadcast applications with increasing levels of layers applied per square metre.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.