High Quality Epoxy Coatings Perth

Contact us today to find out more about our services.

Request a Free Consultation

Our Trusted Clients

Perth’s Leading Epoxy Coating Provider

Looking to reinforce your existing concrete floors without spending big on an entire floor replacement?

Known for its minimalistic design and long-lasting durability, epoxy coatings offer a timeless way to get more out of your concrete flooring. Even better, they come in a variety of types and can be applied whether your flooring is new or old, already coated or not. When professionally installed, they enhance the look of your home, business, or workspaces while saving you money in the long run.

One of the most critical components for a long-lasting floor is proper application. For this, you’ll need to choose a reputable and experienced installer, and there is no one savvier with this flooring solution than the Hawk CFC team.

We’ve served Perth and Western Australia since 2014 with custom resins and locally manufactured materials. This helps us save our customers money while guaranteeing the quality and workmanship behind every job.

If you’re on the fence about this type of upgrade, click here to arrange your 100% free consultation to learn more.

What’s the difference between epoxy flooring and epoxy coatings?

Admittedly, these are quite similar given that their number one component is epoxy.

The difference between these two comes down to thickness.

A coating is just that: a thin layer of a substrate that is added on top of another. The layer is less than two millimetres thick. This is just enough to add protection or design. A full-on floor is one with many layers added one after the other with time in between for adequate curing. The result is flooring with a layer of two millimetres or more thickness.

Are these solutions worth the investment?

They provide a clean, bright appearance and are available in a variety of colours – giving you the flexibility of your own designer floor. You also have your choice of finishes, such as beautiful decorative resin designs that can be modified to achieve a matte, satin, or gloss appearance.

In addition to aesthetic benefits, they provide a multitude of other functional benefits, including:

- Shock resistance: Withstand impacts to protect the concrete below

- Heat resistance: Retains its integrity up to 93.3 degrees celsius

- Chemical resistance: Remains easy to clean with non-porous surface

- Water resistance: Does not absorb or distort due with liquid contact

- Long lasting: Stays intact in residential applications up to 30 years and up to 10 years in commercial settings

- Low maintenance: Requires light sweeping or mopping with infrequent need for extra layer

- Germ resistance: Can be formulated to include antimicrobial protection as needed

Are there different types of epoxy coatings to choose from?

One of the other benefits is the variety available for commercial use.

When you speak with our professional installers, we’ll help educate you on ways you can use your space. This will give us a clear picture of which types will be the best fit for your needs.

For example, some options only make sense in highly industrial applications where others that are more decorative would be less durable in commercial spaces. Here is an overview of the main types to give you an overview of your options:

- Self leveling: Great for home use and install over existing concrete for smooth surfaces

- Mortar: Can repair cracks as well as add a protective layer in industrial spaces

- Graveled: Used decoratively with speckling and a wide variety of colors

- Flaked: Works as a designer floor with multicolored chips that add visual interest

- Antistatic: Perfect for areas near electronics including hospitals and labs

What is the application process?

This process will vary slightly depending on the size of the space, condition of the existing concrete flooring, and the type you choose.

However, these are the general steps that most installers take.

- Prepare the surface by cleaning and removing any dust or debris.

- Clean or prime the surface as required by the type.

- Repair any existing damage including filling cracks, leveling, or stain removal.

- Final cleaning to ensure zero debris in the space.

- Ensure proper ventilation for the space and protective team gear.

- Prep the material and equipment including coloration or mix of flake material.

- Apply the first layer.

- Allow the surface to cure completely.

- Apply subsequent layers with time to cure in between.

- Apply a final sealant coat as needed.

How long does it take to install epoxy coatings?

This typically depends on the total surface area you need coated since larger spaces can take longer to complete.

A professional installer can apply it in a single day, depending on the size of your business. The floor must then be left alone to cure completely before anyone walks on it. This takes another 2-3 days on average. If you are having multiple coats applied, the process will be extended.

Keep in mind that this does not include any time required to prep existing concrete. If your flooring requires repairs, stain removal, or grinding, this will add time onto the project. A professional installer will be able to assess the floor’s condition during an estimate and provide a project time frame along with any pricing for services.

Do they come with a warranty?

Most materials will include a manufacturer limited warranty for the integrity of the epoxy itself.

In tandem with this, you should choose a provider that backs their installation with a workmanship guarantee. Normal wear is expected in high-traffic areas, but you should still be able to expect your new floor to last for many years to come.

Why choose Hawk CFC?

The team at Hawk CFC prides itself on providing a fully comprehensive service, not only from start to finish but throughout the life of your floor. We are dedicated to helping clients assess their needs and delivering the perfect options.

All epoxy coatings we provide in Perth are beautiful, modern, slip-resistant, hardwearing, and UV stable. To ensure you get a solution that lasts a lifetime, we provide you with maintenance checks and ongoing support. Have a look at our long list of happy clients who continue to hire us for new projects and refer new contacts to us.

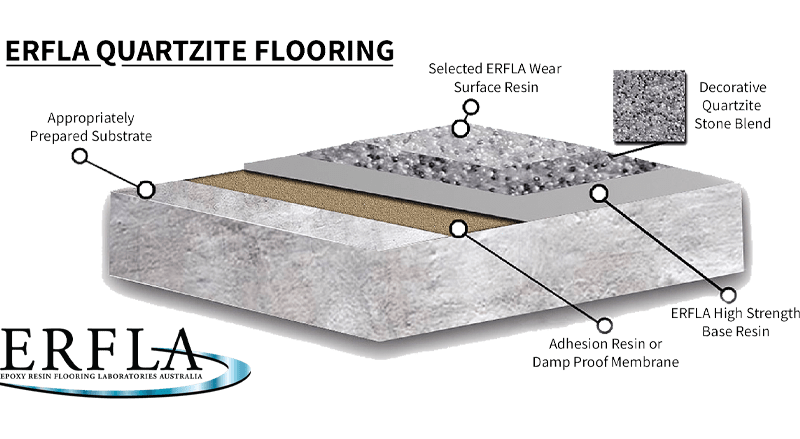

Hawk CFC works with ERFLA-range epoxies, and when it comes to quality assurance and performance resins in Perth, no other brand comes close. Choose from a range of performance options as well as a variety of designer and mono finishes to complete your business, your way.

Call us today on 0490 777 761 or request a free consultation to learn more about the range of epoxy coating in Perth that’s available to you.

Frequently Asked Questions About Perth Epoxy Coatings

When did these coatings become popular?

Epoxy coatings have been around for decades. With technological advances in recent years, new resins have transformed the industry and promoted this material from being a good solution in most instances to being the premium solution for commercial and industrial concrete flooring.

The diversity of this floor is such that it can be installed over existing tiles and floors as well as direct to the concrete. The impressive performance characteristics of these resins include total rejection of bacteria and germs and a seamless, waterproofed, impervious barrier to stains, yet still allows for control-ability of slip resistance ratings.

How many layers will I need?

This will vary depending on your space and how you use it. In general, a minimum of two coats will provide the best colour results and coverage. In case the surface is contaminated, it will also need to be treated with the correct primer. If the concrete is completely free from contaminants and oil, installers may be able to use just one coat of the standard and HB epoxies.

How long will you have to wait before applying a second coat?

It’s important to make sure each layer has time to cure properly. This usually takes at least 12 hours but no more than 48 hours. Even though the floor will seem touch dry after a few hours, it takes much longer than it looks for the coating to fully cure before applying the second coat.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.