Professional Industrial Epoxy Flooring Perth

Contact us today to find out more about our options.

Request a Free Consultation

Our Trusted Clients

Perth’s Respected Specialists For Industrial Epoxy Flooring

Industry is the momentum behind business and innovation the world over. Industrial epoxy flooring does its part in these critical facilities by creating durable, reliable, safe surfaces for progress to happen.

Every company needs a firm foundation. And one way to achieve this is to cross the floor off the list of your concerns. With machines, staff, products, and production lines to manage, who wants to spend time trying to sort out what’s under their feet?

Install the wrong floor in an industrial facility, and you could have a recipe for disaster. People need safe places to walk and surfaces that can be maintained or cleaned no matter what your line of business is. This type stands up to every challenge with customisations that cater to even the most specialised environments.

When it comes to the floors, Hawk CFC is the leading expert in Perth and the surrounding area. We specialise in the flooring that’s made to last and to customer specification. And we don’t just install the best floors: we manufacture all of our products here in Western Australia and back our materials and workmanship with a warranty. If your floors need an update, call us on 0490 777 761 or organise a FREE consultation online.

Is industrial epoxy flooring worth the investment?

“What exactly makes this type of floor so great or worthwhile?”

Can’t you just stick with concrete since it is going to be subjected to so much wear, tear, dirt, dust, and grime? This is a common misconception from business owners and entrepreneurs in the industrial space.

Concrete might do the job, but there are quite a few qualities to this type of floor that outshines basic, untreated concrete.

Surface penetration

Concrete is a porous material and will act like a sponge when it comes to spills. In many industrial applications, there are substances that you will simply not want your floors to hold onto. These might be for cosmetic reasons (i.e. staining) or employee safety (i.e. odors and chemicals). With this type of floor, teams can easily wipe surfaces clear without worrying that the floor will take on whatever comes in contact with it.

Employee safety

Workers deserve safe places where they can perform their tasks. And while some equate this material with slick surfaces, this is quite inaccurate. In fact, non-skid additives create grippy floors that are even safer than bare concrete. In addition, the coatings are resistant to hazardous chemicals, bacteria, grease and other substances from seeping into the floor.

Cost effectiveness

Concrete floors are not among the most expensive to install, but they can be costly to maintain over time. Left unprotected, concrete floors can show signs of wear, scuffing, cracking, and stains. This, in turn, requires regular maintenance, patching, or resurfacing that can add up and potentially disrupt operations. This material prevents this damage from occurring in the first place, saving money and time in the long run.

How can industrial epoxy flooring be tailored to different industries?

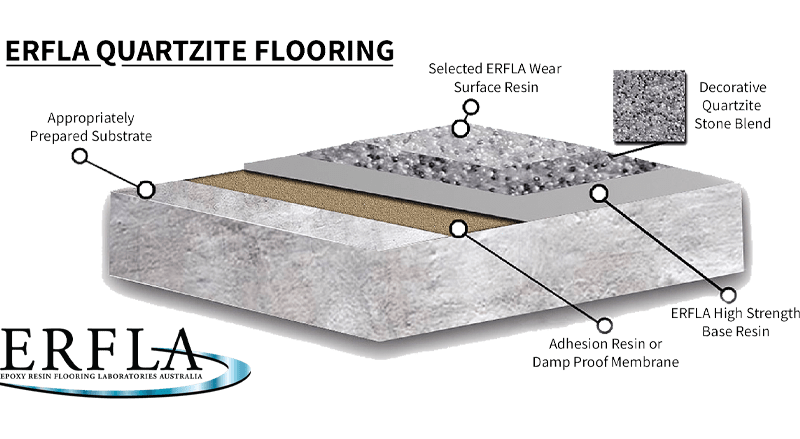

It all starts with the resins, which come in a few different varieties depending on your needs. They can be further customized depending on the specific needs of an industry or application. Here are a few of the most common:

- Anti-static: Installed for manufacturing facilities where electronics and sensitive equipment is used or assembled.

- Anti-microbial: Applied for extra protection in food and beverage plants as well as medical manufacturing plants.

- Anti-skid: Added for production lines with a significant amount of foot traffic and flooring installed in wet areas.

How to get started with an expert installer

Whether you have a fresh concrete slab to protect or an existing floor deserving of added protection, industrial epoxy flooring can be an effective solution.

You’ll need to select a reputable, experienced installer who has direct experience working with industrial spaces like yours. The designs for a pharmaceutical facility can have different requirements than those for a mechanical shop. This familiarity will also help them accurately assess and price out your project with a timeline for completion. You can also benefit from their counsel, with recommendations for the thickness and additives that will suit your space best.

Look for an installer that is fully licensed and insured can give you peace of mind before letting anyone else in your facility. You’ll also want to understand whether they employ their own staff (or use subcontractors) and whether they own their own equipment (or use rentals). This can provide a sense of how established and reliable they’ll be for your project. And don’t be shy about asking for a handful of references for projects similar to yours.

Why Choose Hawk CFC

This floor may look like a basic, shiny floor to the untrained eye. But going with a quality installer who can design a floor especially for your facility is always worthwhile. Often, the professionals you choose are the difference between floors that are safe, sanitary, and strong and those that simply fail.

At Hawk CFC, we understand that every project is different and requires an expert approach. That’s why we start with a free consultation before bringing any new customers on board. We create designs that are an exact match for how your teams will use your spaces so that your flooring will last.

As a manufacturer and installer, we’re able to advise on the entire process, so you get the best floor for your needs. You’ll also benefit from material and workmanship warranties. Call us on 0490 777 761 to learn more about our process.

Frequently Asked Questions About Perth Industrial Epoxy Flooring

What information will the installer need to know about my industrial space?

The more you share, the more they’ll be able to design the right floor for your needs. This often comes down to the working conditions, materials used, and general environmental factors. Be ready to explain whether your space will be subjected to the following:

- Temperature extremes

- Changes in humidity

- Harsh chemicals or oils

- Heavy machinery

- Specific traffic patterns

- Cars, planes, or vehicles

- Sanitation requirements

Can this type of floor withstand extremes in temperature?

Yes. If your facility operates with temperature swings, you won’t have to worry about the flooring expanding, contracting, or degrading over time as a result. A professional installer can also recommend the best solutions for areas of high heat up to 70°C. This floor is also a great solution in freezing temperatures for industrial coolers, freezers, and warehouses.

How long does this floor last in Perth?

While this is arguably the most durable material available, it does have its limits and industrial spaces are known to push them. Professionally installed floors can last 7-10 years depending on how much traffic, pressure, and damage they are subjected to. However, these floors are also easy to refresh, so you don’t have to replace the entire floor once its time is up. The coatings can be applied on top of existing layers to add more protection and continue to extend the life of the concrete underneath.

What are the reasons an industrial floor can fail?

With so much said about how long-lasting flooring is, you can still find instances where the floors simply don’t hold up. This is typically down to improper installation rather than faulty material. This is just another reason why choosing an experienced professional installer is so important. The most common reasons for failure due to installation include trapped moisture, wrong choice of material, and an incorrectly prepared concrete surface.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.