Reliable Non Slip Flooring Perth

Servicing all of Perth, Hawk CFC has over 10 years of experience providing premium durable, non-slip, coating solutions.

Request a Free Consultation

Our Trusted Clients

High Quality Non Slip Flooring

We Offer the Full Range of Non-Slip Industrial Coating Systems

Health and safety is a key component of every workplace. One of the most common threats to human health is the ever-present possibility of a fall, trip, or slip on a poorly maintained floor.

Government regulations hold business owners and management accountable for the level of safety in the workplace and this should impact upon decisions surrounding your floor maintenance. Not only do you need non slip flooring installed, but a maintenance program is essential to ensure hazards are eliminated.

A non-slip epoxy resin floor is ideal because it not only supplies you with the slip rating you require to keep The authorities off your back but it actually makes the maintenance and cleaning routines much easier. In-house routines can be as simple as mopping with the right cleaning products while the floor is still able to withstand commercial cleaning techniques such as high pressure cleaning, rotary scrubbing and degreasing. if maintenance is outsourced, it will save you money on labour costs.

What to consider before purchasing Perth non slip flooring

In most cases and with most flooring products, the higher the slip rating, the more difficult it will be to clean the surface. Slip resistance is achieved with the addition of a slip resistant additive to the mixed resin, leaving a visible granule in the surface. The final level of slip resistance is determined by the level of slip-resistance additive and the film thickness of your top coat. With a high level of slip-resistance additive and a thin film thickness of the top coat makes a rougher surface, which is ultimately more difficult to clean.

Why Hawk CFC’s Slip Resistant Methods are Different

To combat low levels of cleanbility with high levels of slip resistance, we implement multiple strategies to give you an anti slip coating that’s still easy to clean:

1) In some cases, we can use micro-friction additives with a lower surface profile, giving you the feel of a smooth surface whilst still achieving an R10 slip rating.

2) The effective use of top coats. While a highly slip resistant floor has large traction particles, the use of top coats can take away the sharpness and “catch”

3) Specifying the correct floor and slip rated surface: there’s no need for a R12/13 in every instance, get the right advice!

4) We can provide options for your cleaning techniques. A highly non slip flooring (R13), would normally grip oils and stains, making cleaning difficult. However, the durability of our industrial coatings means you will be able to use cleaning equipment such as high pressure or rotary devices without damaging your floor.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

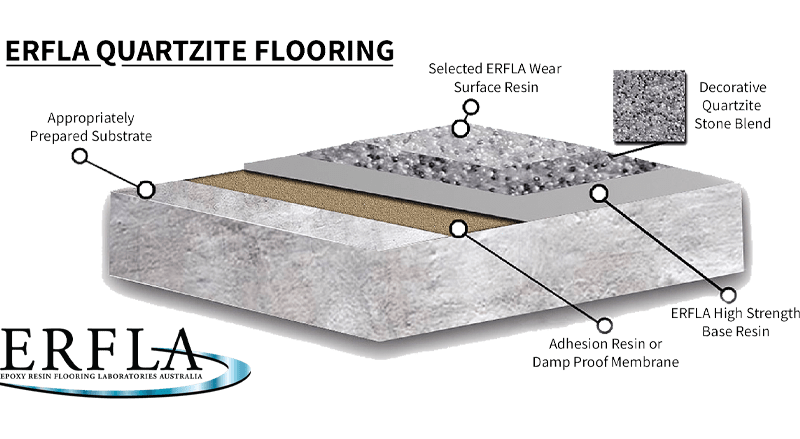

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.