High-Quality Polished Concrete Floors Perth

Explore how your floor can take your space from drab to designer with solutions that can last a lifetime.

Request a Free Consultation

Our Trusted Clients

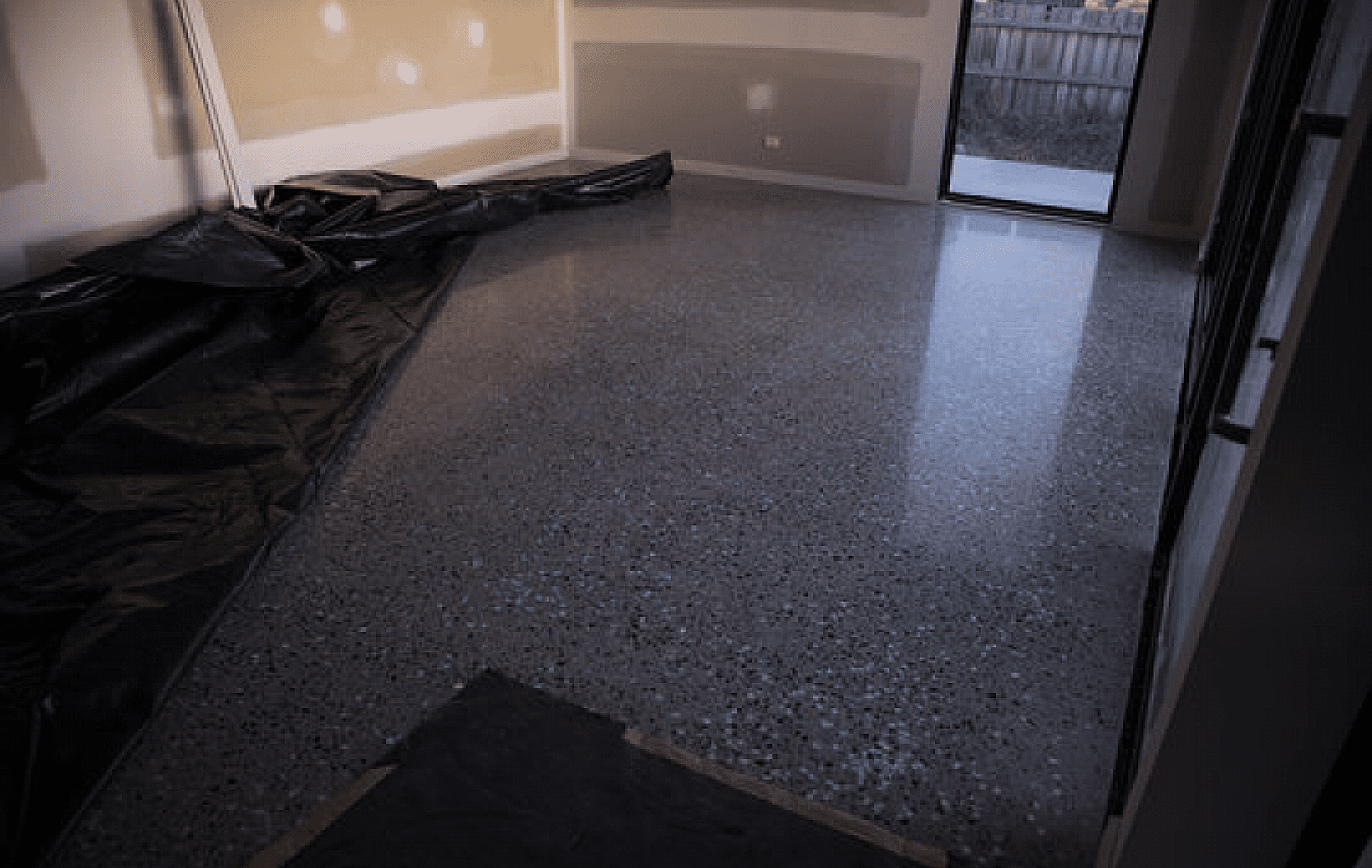

Polished Concrete Floors

We provide stunning polished concrete floors in Perth and throughout Western Australia.

Watch the video below to see European Ceramics’ new floor in their Osborne Park showroom. This highly versatile floor is finished with the Silikal Satin resin to give it its smooth stunning style.

If you want to learn more, check out our articles:

Polished floor adds design and durability to any space. Originally thought to be suited for only industrial or commercial spaces, these floors are now in demand as a designer flooring option in residential properties as well. Not only does it have a stylish and modern look, this material is also hard wearing and highly sustainable.

We have offered services for new and existing surfaces throughout Western Australia since 2014. Our CM3-qualified team consults with clients the best approach and outcome to every project.

Why consider polished concrete floors in Perth?

This material offers businesses and homeowners a variety of benefits such as extreme durability, very low maintenance, easy cleaning, allergen-free surfaces, and an aesthetically pleasing look. These flooring systems are achieved through a series of mechanical grinding and polishing processes including:

These processes provide an aesthetically pleasing surface that is hard wearing, easily maintainable and will provide a long-lasting asset to your home or business.

Are there different polishing options available?

You can achieve a number of different looks through three different methods: exposure, shine, and sealant.

Stone Exposure: When grinding the surface, it is possible to hone a slab, removing enough of the surface cream to expose stones or aggregate within. There are many terms for describing exposure levels. We offer four options: none, light, medium, or heavy exposure.

Shine Level: Achieving a reflective surface is produced by progressive mechanical polishing by using resin-based pads, ranging from 50 grit to 3000 grit. This lets providers achieve a tailored level of shine that meets your requirements.

Sealant Type: Typically, a penetrating, reactive sealant should be used when polishing the floors. You can also choose from more eco-friendly, water-based sealants which are great option that does not sacrifice durability or design.

How much do polished concrete floors in Perth cost?

Quite a few factors go into creating an accurate estimate for a flooring project. To polish the surface, different machinery is required to achieve the look and feel desired. The costs for any project will include the use and transportation of that equipment.

The cost can also vary depending on the way that the surface is polished. In addition to the process type, other issues can affect the pricing including:

How long does the polishing process take?

This is largely a factor of the size of the floor that you need polished. If you are in the middle of a new build, it can be easier and quicker to have the surface polished before the structure is framed or divided into distinct spaces. A smaller job in a residential space may take 2-3 days to complete, but larger projects can take 4-7 days to complete in usual circumstances. A professional service will be able to give you a quote that includes an estimate for timing for each stage of the process.

Are these floors difficult to maintain?

These floors are a very low maintenance flooring system when compared to other flooring options. Cleaning is as simple as using a microfiber mop with a neutral cleaning agent. Of course, normal wear and tear is a fact of life and will occur on any flooring surface. Regular cleaning and occasional sealant re-application are recommended to ensure your surface lasts a lifetime.

Another important factor to consider when creating a polished surface is that densifiers and penetrative sealers do not create a completely impervious surface. While chemical and moisture absorption is heavily reduced, sealants are designed to allow the surface to breathe. This can result in shadowing on the surface if moisture finds its way in over time.

Why you should choose HAWK CFC

We have been the leading provider of flooring services in Perth and the whole of Western Australia since 2014. We stand by our work and offer a delamination warranty that covers the materials and the workmanship for every project. Our CM3-qualified team also specializes in HACCP Accredited Silikal GmbH Reactive Resins which have a wide range of commercial applications.

We’re dedicated to creating flooring made from safe, hygienic, low-maintenance flooring that is also beautiful to look at. HAWK CFC is standing by to offer you a fast free quote. You can also call us on 0490 777 761, and we’ll be happy to answer any of your flooring questions.

Frequently Asked Questions about Polished Concrete in Perth

How do you get started with the polishing process?

Any professional installer will need to understand the size of the flooring area as well as durability and design needs. Each of our projects starts with a free detailed consultation to provide the right floor that meets any number of possible outcomes. Some important factors to think about when considering your flooring are:

With these details sorted out, the space will be cleared and cleaned to prep for polishing. If there is any damage or cracking, this will be repaired at this stage. The floors will be polished in stages to achieve the desired look, which clean up occurring along the way. The floors will then be sealed, sometimes with multiple coats, to protect the surface and achieve additional shine. If you are having the flooring textured, colored, or stained, this is also the time for design elements to be added. The polished must be left to completely dry and set before it is used.

Can you polish the existing surface in my home or business?

The condition of the surface is without doubt the most important factor to consider. The surface will need to be structurally sound and hard enough to be polished. Typically, 25 mpa is considered the minimum strength, with some specifications requiring 32 mpa or higher. Check to see if you have cracks, divots, or pin holes on the surface. Although these can be patched and repaired, they will always be visible in the finished product.

Will having my floors polished make a mess in my business or home?

Most professional services will have top-notch equipment that eliminates or reduces dust. Dry polish methods using proper vacuum systems will produce almost no dust. Wet grinds will produce a mix of water and particles, but these are siphoned off of the ground along the way. You will need to clear the space completely of all contents including furniture and fixtures, which can create a bit of a storage challenge.

Are polished concrete floors going to be slippery to walk on?

The high-gloss look can make them look slick and slippery. However, they do not need to be difficult to walk on. When installed by a professional, the floors can actually have quite a bit of traction.

Why Choose Us

West Australian Owned and Operated

Proudly Western Australian since 2014.

Guarantee

Ask us about our Delamination Warranty that covers both Materials used and Workmanship.

Custom Resins

Our Western Australian plant allows us to produce specific resins for our clients.

MANY Industries

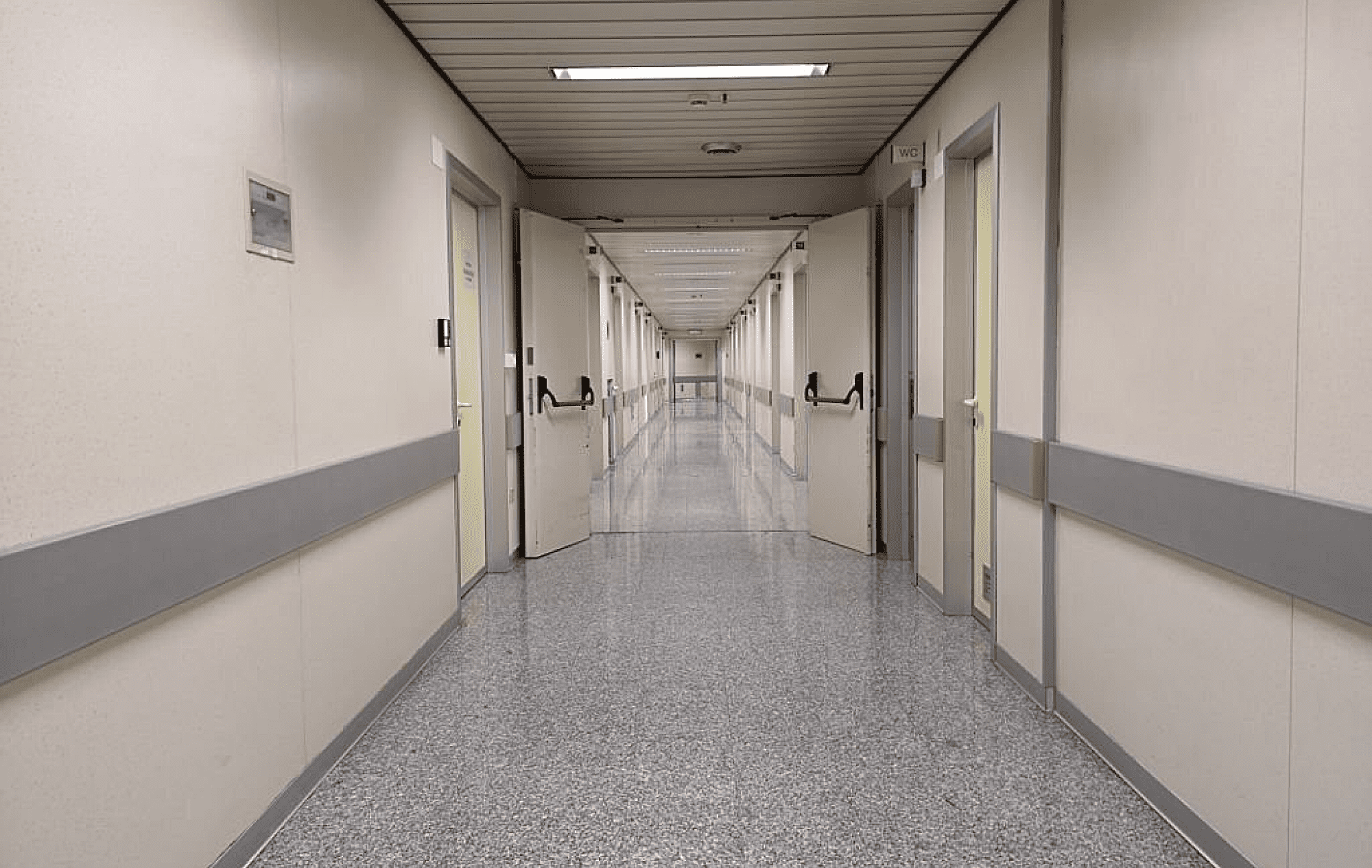

We work with commercial sectors, the food industry, pharmaceutical, healthcare, mechanical and equipment workshops, etc.

Non-Slip

We tailor-make your floor to achieve the desired cleanability and slip resistance rating.

FREE Consultation

Choosing a floor can be challenging. We’re here to guide you along every step of the way with neutral advice on what floor is the right option for your business.

Safety First

Safety is at the core of our business values. Ask us how we can keep your team safe.

From Manufacturing To Installation

We are the only West Australian installation company with its own local manufacturing plant. We can handle the entire process from production to installation to save you money.

Flooring For LIFE

In 2014, we proposed to transform the food industry by removing the “grout & seams”. Specialising in HACCP Accredited Silikal© GmbH Reactive Resins, we are passionate about providing our customers with seamless, easy-to-use non-slip surfaces.

Our Trusted Suppliers

RRTS – Rapid Return To Service Flooring

We specialise in minimising your downtime. We have heavy equipment to prep fast and rapid cure resins which often allow for an immediate cure.

Comprehensive Solutions Through Distributorships

We are the West Australian distributor for Silikal GmbH and Alluvius, as well as many accreditations for alternate suppliers.

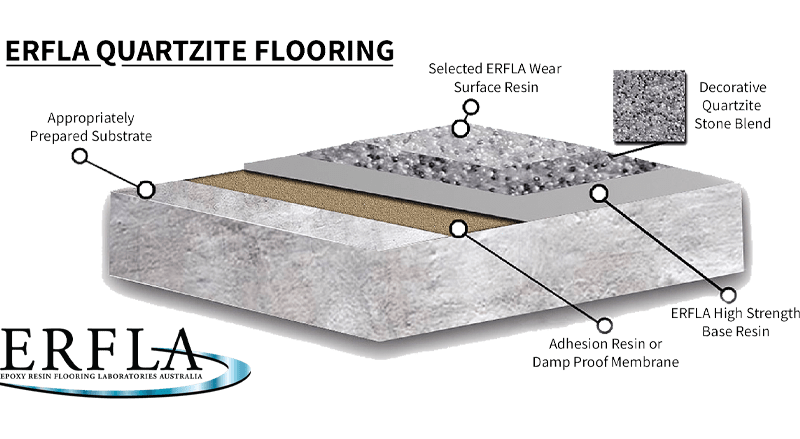

Multi-Layered Specialty Systems

Allow us to specify a system that takes into account your unique environment and goals.

Flex-Plate

Flex-Plate is found exclusivity at Hawk CFC.

CM3

We’re happy to show our health and safety capabilities.

Zero VOC Flooring

We offer beautiful, non-toxic, eco-friendly floors.

Our Certifications

In food safety management, a fundamental approach to managing risk is implementing a HACCP system.

This acronym stands for Hazard Analysis and Critical Control Point.

The development of a HACCP plan must identify and manage the following types of hazards: Biological, Chemical, Physical, Allergens, Quality, and Regulatory.

Our Work

What Our Clients Are Saying..

Thanks to the Hawk CFC Team for your contribution to our company- great knowledge, and attention to detail, and a professional team.

Rhett is one of the best trade business owners I have met. Our renovation had complications, but he and his guys have worked tirelessly to achieve a unique and awesome floor. I’ve had some great trades on our recent renovation and Rhett has stood out as honest and passionate about what he does.

Hawk Concrete Floor Coatings did an outstanding job with the high pressure clean and sealing of our driveway, garage & paving! Team were friendly & professional. We are actually getting more paving done with our landscaping, will need them back to seal the new paving too. Highly recommend Hawk for your next job residential or commercial.

These guys did an amazing job on our kitchen floor and dining floor in our Fremantle cafe. Everyone is impressed and the health department loves it. Couldn’t recommend them more highly. Thanks guys.

They are an amazing bunch of people. Really high standards set and maintained in all aspects of the job.

Connected with Hawk Concrete Floor Coatings through hipages.com.au and we have confirmed that they would recommend them.